Trump Inherited a Shipbuilding Disaster

From Paradigm Press, we hope your Thanksgiving holiday was enjoyable. Now that December is here and the year draws to a close, let’s dive right into the pressing matters at hand.

Today we’ll examine the dire state of U.S. shipbuilding overall, with a special focus on Navy ship construction. It’s a tangled and troubled situation, as outlined below. Although President Trump inherited this challenge from previous administrations, it now falls squarely on his shoulders to address it.

In short, America’s shipbuilding difficulties have been accumulating for more than three decades, involving multiple parties and requiring a long, costly effort to resolve.

You might think naval shipbuilding isn’t relevant to your investment plans, but what’s unfolding on the water is crucial for both the economy and national security. Plus, there are opportunities to profit from select companies, some of which I’ll highlight below.

To paraphrase Leon Trotsky from 100 years ago, “You may not be interested in shipbuilding, but shipbuilding is interested in you.”

With that in mind, let’s cast off the dock lines and set sail…

Image of proposed USS Constellation (FFG-62). Courtesy Fincantieri Marinette Marine.

Another Failed Navy Program…

While driving through Pennsylvania last week, I caught a broadcast near Bedford County where someone mentioned that the Secretary of the Navy had just declared the “Constellation-class” frigate program cancelled. Wait, what?

As a former Navy man who keeps tabs on these topics, I knew cancelling a major Navy program is significant. Curious, I pulled over and checked my phone to understand the full story.

Here’s the context: The U.S. Navy is shrinking. We have many aging vessels but not enough replacements. The “600-ship Navy” goal from the Reagan era was never fulfilled, a fact I know firsthand from time spent in the Chief of Naval Operations office during my naval career.

Currently, roughly 280 ships are commissioned at any given time. Many are fully operational, deployed globally from Japan and the Middle East to the Caribbean. Others remain stateside for training or preparation, while quite a few are undergoing extensive maintenance or repairs dockside or in shipyards, thus unavailable for immediate missions.

The world remains vast, with over 70% covered by ocean. Navy responsibilities cover everything from polar regions to every major ocean basin worldwide.

Simply put, the Navy faces countless tasks but lacks sufficient ships and sailors to fulfill them. The mantra of doing “more with less” only lasts so long before ships and crews become worn down, leading to a decline in capability despite leadership’s reluctance to admit it.

To briefly summarize the fleet expansion effort, some years back the Navy and Congress opted to adopt a European frigate design—originating from Italy and France—as a relatively affordable, ready-made option. This plan was appealing since these ships were already operational in European navies. The idea was to modify the design slightly for U.S. standards, build them domestically, and get new vessels out quickly.

Sounds great, right? A proven design with NATO commonality. Set up production in an American shipyard, manufacture these European-style frigates efficiently, increase hull counts, expand capabilities—classic upbeat rhetoric.

Initially, promises were made that the U.S. version would retain 85% of the original design with only 15% customized to fit American needs. This sounded reasonable and achievable.

But then the typical American approach took over—countless tweaks, endless design changes, and creeping modifications. For instance, replacing the European powerplant with an American engine affected size, weight, center of gravity, hull strength, wiring, fuel, and control systems.

European weapons were swapped out for U.S. armaments, requiring new mounts, missile defenses, and redesigns to combat systems.

European electronics had to be replaced with American gear, necessitating further adjustments to power supplies, wiring, antennas, and sonar systems.

Plus, the U.S. Navy typically operates with larger crews, mandating more bunks, storage, fresh water capacity, and additional infrastructure.

You see how this spiraled, right? What started as a mostly shared design became almost entirely a U.S.-specific project. Costs soared and construction timelines stretched indefinitely. Worse yet, shipyards began cutting metal without a final design in hand.

At a defense conference last spring, I spoke with a naval architect contracting for the Navy who shared her frustration: “We can create whatever the Navy demands, but the repeated shifts in requirements mean the design is never frozen. The ship is a moving target, and it’s not even built yet.”

Fast forward to last week, just before Thanksgiving, when Secretary of the Navy John Phelan announced plans to produce only two of these Euro-inspired ships—already underway in the Wisconsin Fincantieri Marinette Marine shipyard. The next four planned vessels and all future options are cancelled.

This adds another failed Navy ship program to previous costly disappointments, like the three-ship Zumwalt-class (DDG-1000) stealth destroyers that struggled to find a mission, and the infamously problematic Littoral Combat Ship (LCS) program, often derided by Navy personnel as “Little Crappy Ships” after early sea trials revealed serious flaws.

The entire situation is chaotic. It calls to mind the words of British Vice Admiral David Beatty, later First Sea Lord, who after the 1916 Battle of Jutland remarked, “There seems to be something wrong with our bloody ships today,” as he witnessed two battlecruisers destroyed by German fire.

Let’s Play Blame Games

Yes, this mess demands accountability—should we solely fault the Navy? Current and past admirals and the folks at Naval Sea Systems Command are certainly responsible for tinkering excessively with a workable European design. (Answer: yes.)

But on a deeper level, why doesn’t the Navy maintain an extensive, up-to-date catalog of modern ship designs ready for production? Countries like Russia and China have this capability.

Still, blaming the Navy alone ignores a wider network: federal agencies, maritime states and locals, and big defense contractors all share the blame.

The problem isn’t just blue uniforms. Some of the sharpest naval insights come from retired Navy officer Commander Salamander and ex-Merchant Marine captain John Konrad, both active on X/Twitter and Substack.

Konrad recently remarked, “The primary purpose of a frigate is convoying Merchant Marine ships. Who uses merchant ships most in wartime? The Air Force. Those bombs are heavy, and they drop a lot. Planes drink tons of fuel too.”

In other words, the Air Force heavily relies on sea transport logistics since even all its C-17s combined can’t match the cargo capacity of a single medium-sized tanker or freighter. That said, Air Force General Randall Reed, leading U.S. Transportation Command, gave an excellent lecture this spring clearly demonstrating his grasp of logistics and shipping. So there is some hope.

What about the Army, which long ago offloaded its pre-positioned logistics ships? And the ever-dwindling Corps of Engineers, responsible for building and maintaining river and harbor infrastructure? Where are the dredges, barge cranes, and heavy equipment needed for such tasks?

Konrad also notes that the commercial shipbuilding industry relies on countless suppliers nationwide—all stretched to their limits. But supporting these critical firms isn’t the Navy’s role—it falls to the Departments of Treasury and Commerce.

Labor shortages plague shipyards themselves. Who encouraged the shift of recent generations away from skilled trades towards college degrees, often leaving graduates with large debt and limited practical abilities? Cultural trends and the education system’s easy borrowing policies extended youth, incentivizing impractical fields of study. Again, this roadmap to decline was charted outside the Navy.

As for commercial shipbuilding, a minor slice of the U.S. economy dwarfed by foreign rivals, mostly China, the Department of Transportation and the U.S. Maritime Administration (MARAD) are in charge of advocacy—the latter currently led by an acting administrator due to the Trump administration’s failure to appoint a permanent head.

For shipyard operators, red tape is a major burden—federal regulation from agencies like the EPA and Labor, complex tax codes, IRS oversight, plus state and local governments and legal systems prone to litigation and enforcement actions weigh heavily.

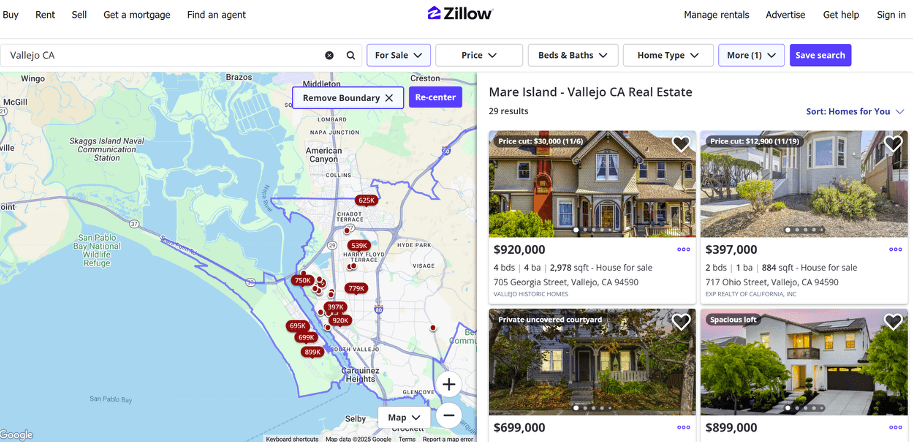

Then consider the investment climate: waterfront lands that once anchored vital shipbuilding operations are increasingly converted to condos and retail spaces. For example, the historic Naval Shipyard at Mare Island, California, was closed in the 1990s and sold for large-scale housing development. (Thanks, President Clinton.)

Zillow site; homes on Mare Island, Calif, former naval shipyard. Screen shot.

Looking Ahead With (Just a Little) Hope

Back to John Konrad: “There are a few dozen critical problems with shipbuilding that the Navy has nothing to do with, which is why it’s essential for Navy admirals to speak up more.”

Meaning, the Navy must advocate for its shipbuilding needs beyond defense circles, reaching into sectors such as law, commerce, finance, environmental regulation, labor, and beyond.

According to Konrad, “One big reason Phelan was appointed Secretary of the Navy is his financial expertise to boost shipbuilders’ balance sheets. He can do that, but he’s busy. And yet, isn’t keeping commercial firms afloat the responsibility of Treasury and Commerce, not the Navy?”

Meanwhile, Konrad observes, “The Navy is trying to fix issues it neither controls nor has enough resources to solve.”

He describes a recent Navy effort in which teams spent days surveying conditions at old shipyards in hopes of reactivation. Yet, charting water depths and bottom conditions truly falls to the Army Corps of Engineers, not the Navy.

When the Navy identified silted-in facilities, they dismissed them because they lack dredging capability—which also is the Army’s responsibility.

The bottom line: many entities must coordinate and clarify responsibilities to repair shipbuilding and Navy readiness. And wouldn’t it be ideal if a strong leader at the top, experienced in large-scale construction with the ability to enforce accountability, were at the helm? If only.

Meanwhile, the major Navy shipbuilders include Huntington Ingalls (HII), responsible for aircraft carriers, numerous surface combatants, and some submarines; General Dynamics (GD), building submarines and surface ships; plus Leidos Holdings (LDOS), owner of Gibbs & Cox, a leading naval architecture firm with around 90 years designing Navy vessels. All three are positioned for success in coming years.

There is more to discuss, but this covers the essentials. Most importantly, President Trump and his team must step up to repair U.S. shipbuilding and strengthen the Navy.

Thank you for subscribing and reading. Best wishes…